News

D&L Industries pushing boundaries in plastics sustainability by harnessing the potential of natural fibers like Abaca

January 14, 2025 – D&L Industries, through its subsidiary D&L Polymer & Colours, Inc. (DLPC), is spearheading technological advancements in making plastics sustainable by successfully developing a pioneering technology in the country that turns an otherwise worthless pile of natural fibers into an eco-friendly complementary material or alternative to plastics.

“The Philippines has an endless supply of natural fibers that are mostly deemed as waste. About 25 years ago, even before the term ESG or sustainability became mainstream, we had already started exploring the possibilities of harnessing the potential of abaca fiber as an environmentally friendly complementary material or alternative to plastics. However, the technology to properly process abaca fibers at scale did not exist at the time, given its extraordinary strength known as the world’s strongest. More than two decades later, with the various advancements in technology, we are finally seeing our vision come to fruition,” DLPC President and CEO Lester Lao remarked.

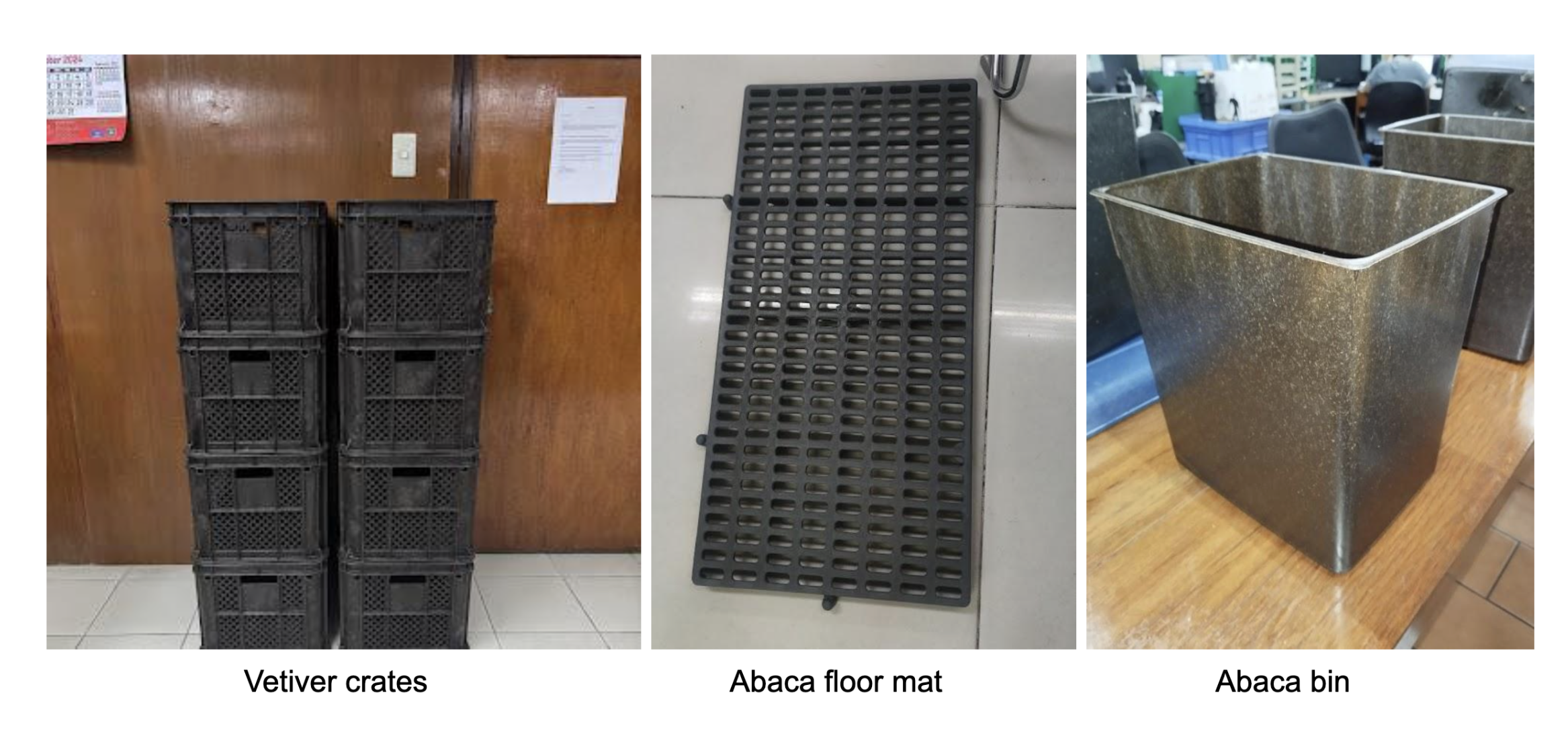

While DLPC has initially used abaca fiber as the base material, the technology has proven flexible enough to use other locally-found fibers such those from pineapple, spider-lily or bakong, and vetiver. The resulting natural fiber composites can replace up to 40% of polymers in the formulation of the various consumer and industrial products that are traditionally made of plastics. Thus, helping minimize plastic usage.

Natural fiber composites have inherent properties that can complement or enhance plastic’s natural mechanical and chemical properties while making it more sustainable at the same time. These composites are stronger and more resilient while being lightweight enough to float in water. Given these extraordinary properties, natural fiber composites have a wide array of potential applications ranging from everyday consumer durables to industrial applications in the construction and automotive industries, among others. At the end of their normal life cycle, products made from natural fiber composites can be recycled or diverted using the typical waste systems. It can also be made compostable for better circularity.

Following the breakthrough in turning the concept into a working technology, DLPC is currently doing the ground work to make it available and used at scale. The company is simultaneously developing various applications while creating the market and educating customers about the practical applications for the technology. DLPC is currently in talks with several potential partners that are interested in using natural fiber composites in making their plastic products more sustainable.

“What we have developed is a totally new material that is arguably breaking the boundaries of polymer science. With its unique characteristics and sustainable aspects, we are convinced that it has the potential to revolutionize the plastics industry,” Lao added.

“With the majority of the people in the industry not yet familiar with the technology and its potential applications, we believe that we are exploring uncharted territory with endless opportunities for innovators and pioneers like us. At this point, we believe that we are merely scratching the surface for a multitude of industries,” Lao concluded.